High quality supplier platform for in-depth certification of national battery industry product query system.

Login/Registion

Service Phone:4000-110-181

<

>

Favor

Favor

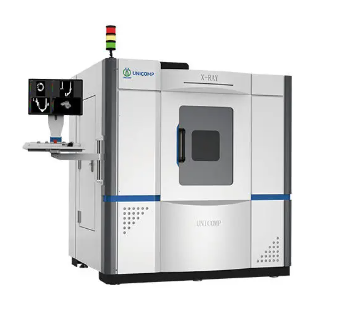

Cylindrical Battery X-Ray Online Inspection Machine LX-1Y120-120

model/specification:

LX-1Y120-120

Scope of application:

18650 Cylindrical Battery

purpose/function:

accuracy:

I want an inquiry View Phone Number

Wuxi Unicomp Technology Co., Ltd.

Jiangsu

Main products:

XRay testing equipment, industrial X-ray testing equipment, X-ray non-destructive testing equipment, lithium battery new energy testing equipment, industrial non-destructive testing equipment

XRay testing equipment, industrial X-ray testing equipment, X-ray non-destructive testing equipment, lithium battery new energy testing equipment, industrial non-destructive testing equipment

∧

- LX2000-130KV Inline X-Ray Inspection Equipment

- Power Winding Battery X-Ray Online Detection Machine LX-2D24-100

- In-line Polymer Lithium Battery X-ray Detector LX-2R30-100

- Prismatic Lithium-ion Battery In-line De

- AX8200 X-Ray Inspection Equipment

- AX8500 X-Ray Inspection Equipment

- In-line Laminated Power Lithium Battery X-ray Detector

- Lithium Battey X-ray Off-line Inspection Equipment

- CX3000 X-Ray Inspection Equipment

- AX9100 X-Ray Inspection Equipment

- AX7900 X-Ray Inspection Equipment

- X-ray Inline Automatic Inspection Machine LX9200

- AX8200MAX X-Ray Inspection Equipment

- 90kV Microfocus X-ray Source

- 130kV Microfocus X-ray Source

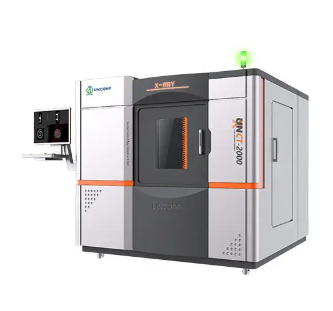

- UNCT2000 - Industrial CT X Ray Inspection Equipment

- UNCT1000 - Industrial CT X Ray Inspection Equipment

- AX9500- Standalone 3D X-ray Inspection Equipment

∨

Detailed Parameters

Detailed Instruction

Features

1, micro-focus, the image is more clear;

2, turntable institutions, efficient and stable;

3, the magnification can be adjusted;

4, easy parameter setting, automatic judgment sorting bad product;

5, user-friendly software interface, easy to get started;

6, fully automated operations, reduce manpower, reduce production costs, improve production efficiency and quality consistency;

7, the software automatically determine, improve product consistency and quality assurance;

8, comes with SPC software analysis, easy process control and quality data analysis;

9, designed to take full account of safety factors to ensure the safety of personal protection;

10, the appearance of beautiful, generous, enhance the corporate image.

Parameter

| System Parameters | Dimension(L×W×H) | 3300mmX1500mmX2000mm |

| Weight | 2.5t | |

| Working Environment | 0~40℃ | |

| Power | 4KW | |

| Accuracy | ±60μm | |

| Operating Mode | In-line | |

| X-ray Tube | Type | Closed |

| Max.Voltage | 110kv | |

| Max.Current | 0.45mA | |

| Focal Spot Size | 15um | |

| Quantity | 1/2 | |

| Image Detector | Type | Image Intensifier |

| Resolution | 110 Lp/cm | |

| Size | 4” | |

| Quantity | 1/2 | |

| Applied to | 18650 Cylindrical Battery | |

| Max.Capacity | 60ppm/130ppm | |

| Operation Ratio | ≥95% | |

| Applicable Size | 18650 Cylindrical Battery | |

| Items | Alignment Metric | |

| Customer Cases | Panasonic /DLG/Liaoning BICO | |

| Equipment Features | *Applicable to the detection of cylindrical batteries like 18,26 series ; | |

| *High speed, high stability ; | ||

| *Modular design with high expansibility, customized automatic battery loading and unloading | ||

| *Automatic docking with production lines, unattended operation; | ||

| *Unicomp-owned R&D of in-line lithium battery inspection software system | ||