High quality supplier platform for in-depth certification of national battery industry product query system.

Login/Registion

Service Phone:4000-110-181

Favor

Favor

Application

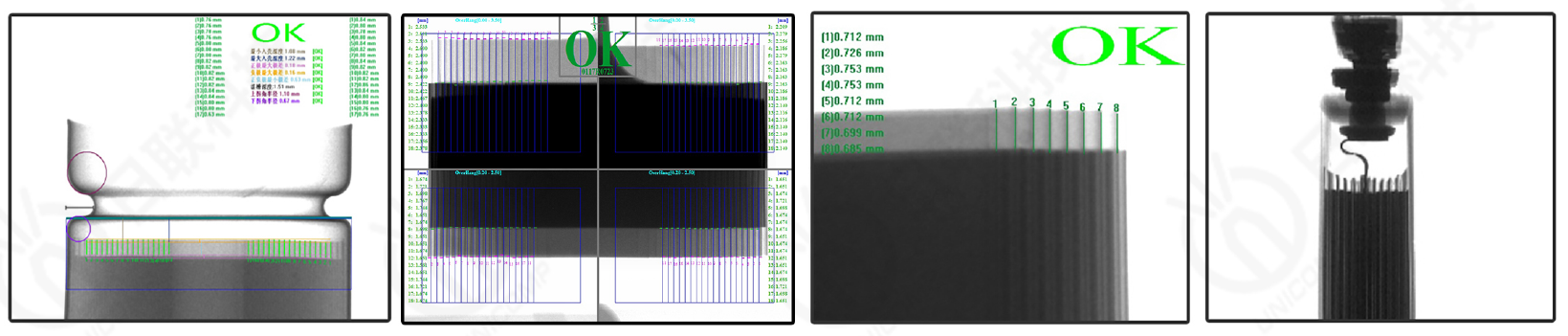

Lithium battery pole piece solder joint defect detection,

Lithium battery batteries coiling case detection,

BGA, CSP , LED , Flip Chip , Semiconductor,

Battery Industry,Small Metal Casting,

Electronic Connector Module,

Aerospace Components , Photovoltaic Industry,

Other Special Industries.

Features

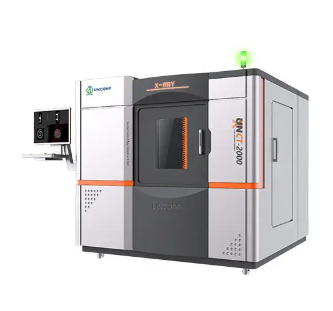

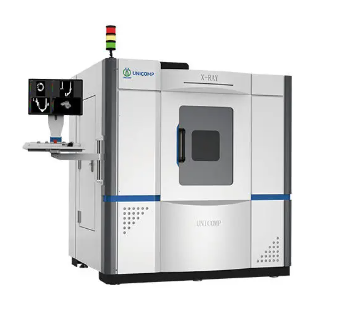

●Off-line lithium battery detection equipment

●Closed 5um closed X-ray tube, Hi-resolution detector

●X-ray tube and detector can be programmed to move to Z Axis positions

●Automatic control of all the moving parts, CNC programming

●Convenient target point positioning system

●Automation software judgments detection

X-Ray Images

| System Summary | |

| Footprint | 1080(W)×1180(D)×1730(H)mm |

| Machine Weight | 1150 kg |

| Power Supply | AC 110~220V, 50/60Hz |

| Plywood Packing Size | 146(W)×128(D)×196(H)cm |

| Packing Weight | 1160 kg |

| Power Consumption | 2.0 kW |

| X-Ray Tube | |

| Tube Type | Closed |

| Max. Power | 8W / 40W |

| Voltage | 0~130kV (Adjustable) |

| Focus Spot Size | 5μm |

| Imaging System | |

| Detector | Flat Panel Detector (option 4’’ i.i. Detector) |

| Pixel Size | 85μm |

| Effective Detection Area | 130*130mm |

| Frame Rates | 20fps |

| Pixel Matrix | 1536*1536 |

| System Magnification | 600X |

| Motion Control System | |

| Movement Control | Joystick, Keypad & Mouse |

| Max. Loading Area/Weight | 520*500mm / 10kg |

| Max. Inspection Area | 360*420mm |

| Oblique Views | Max. ±60° |

| Manipulator | 4-axis with X / Y / Z1 / Z2 |

| Industrial PC | |

| Monitor | 22’’ FHD LCD Display |

| System OS | Windows 10 64bit |

| Hard disk | 1TB |

| RAM | 8GB |

| CPU model | Intel i7 Processor |

| Other Features | |

| Energy Saving | X-Ray Auto-off when it's out of work over than 5 minutes |

| Safety Operation | Electromagnetic Interlock and warning Light |

| Portable Design | Mounted with Wheels on Machine Bottom |

| X-Ray Safety | <1μSv/h (Meets All International Standards) |

| * Specifications are subject to change without notice, All trademarks are the property of the system maker. | |