Favor

Favor

Manufacturing and sales of battery mechanical equipment

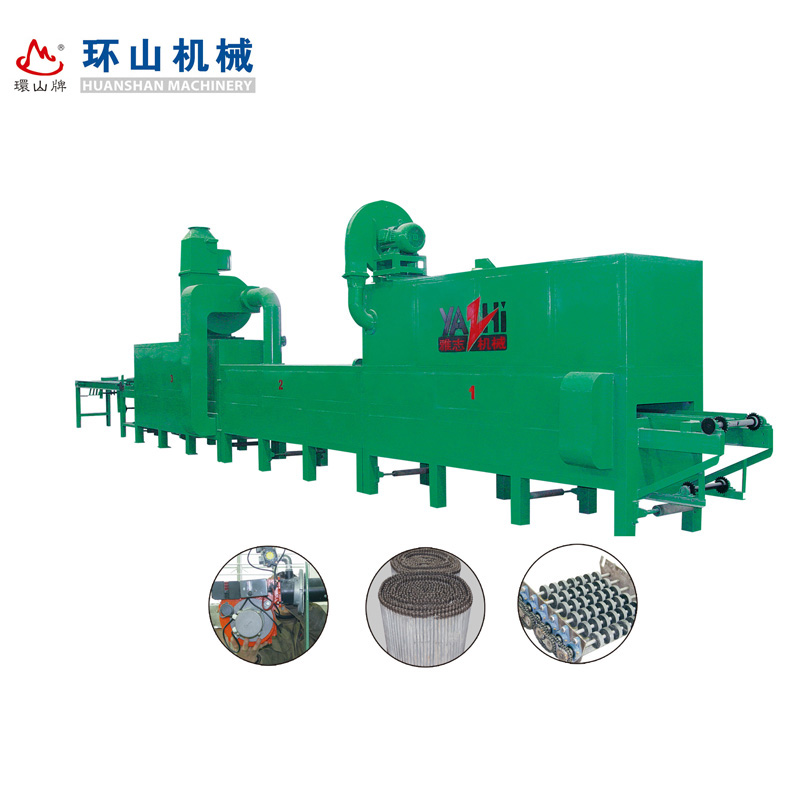

- QL Lead Dice Cutter Set

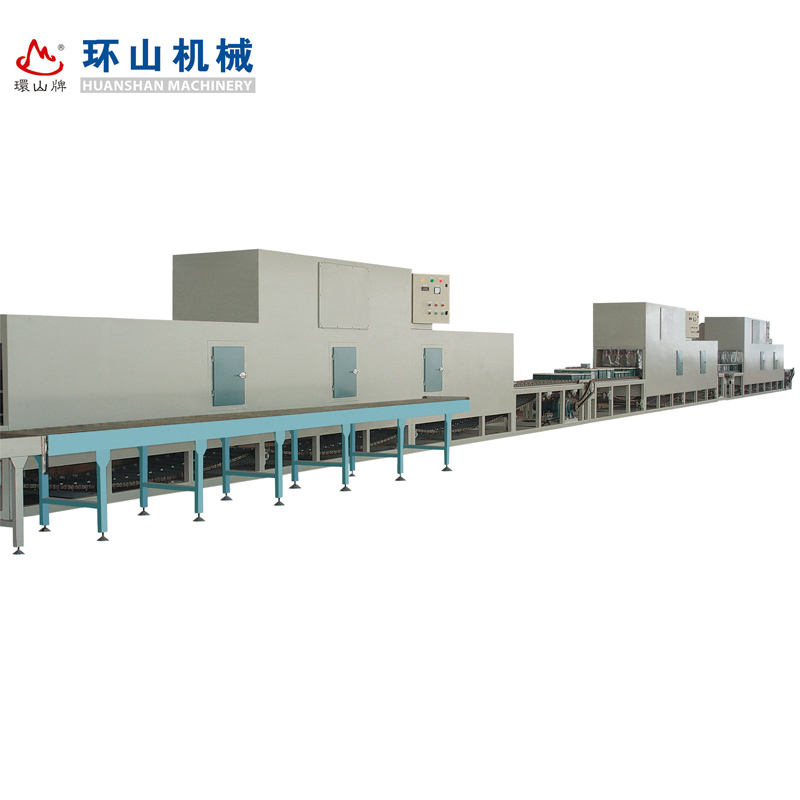

- Plate surface drying line

- Small VRLA, E-Bike Battery Assembly Line

- JBHG Drying Oven After Formation

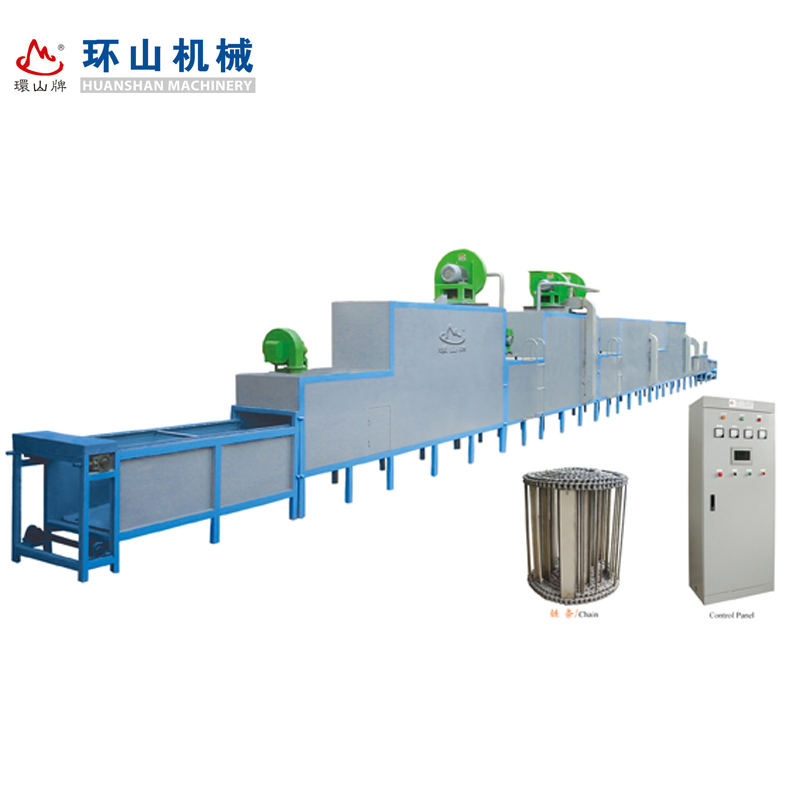

- Plate curing and drying chamber

- ZLJ-20 Lead Cylinder casting Machine

- QMJB Serial Oxide Ball Mill Set

- Serials of HGJ Paste Mixing Machine Set

- HSZH-01 COS For VRLA Battery

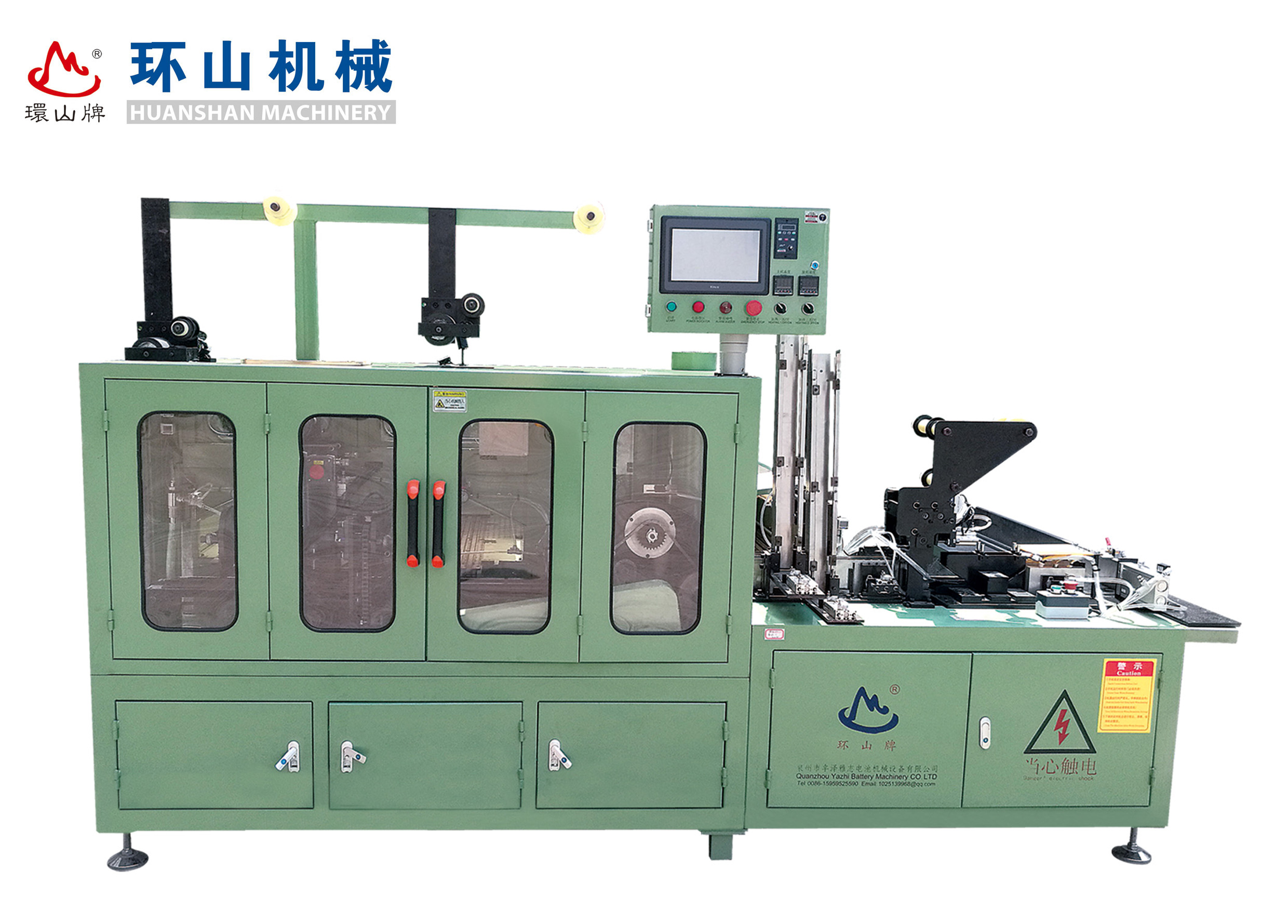

- AGM Wrapping And Stacking Machine For Medium Size VRLA Battery

- HSBP-B Multichannel Side Negative Plate Side Separator AGM Machine For VRLA Battery

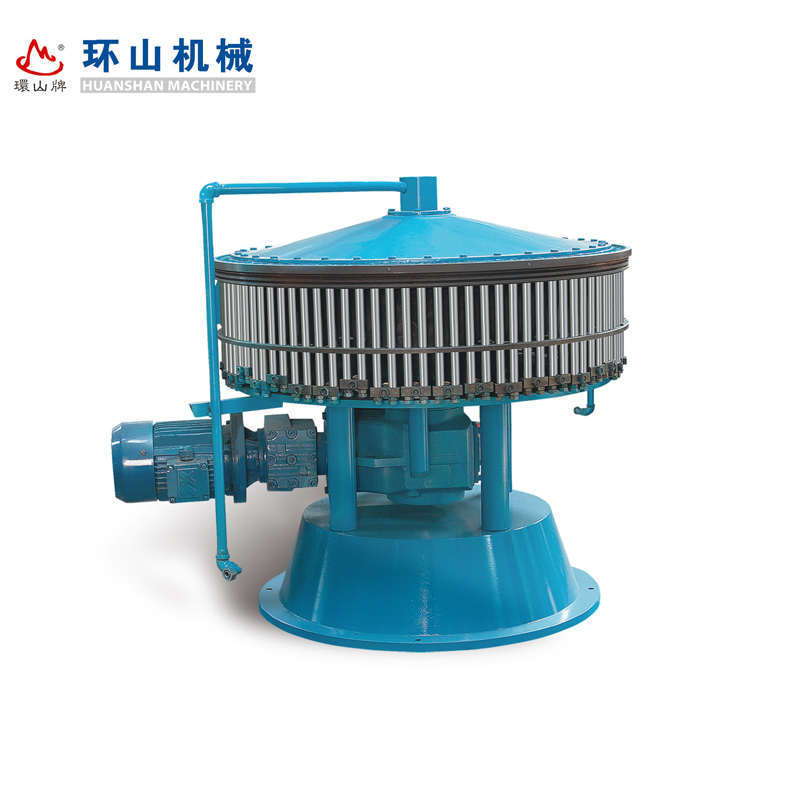

- 摩天轮式中密电池包板机

- HSBP-B多通道边负板边隔板小密电池全自动高速包板机

Combining with many years’ practicing experiences and analyzing the advantages and disadvantages of curing and drying system produced by many manufacturers at home and abroad, we have designed HSGG curing and drying system which reached a domestic advanced level.

The major features of this system:

a. It can be classified into integrative curing / drying and separated curing / drying by mode.

b. It can be classified into electric heating, fuel or steam heating by sorts of fuels. Users can freely select by themselves.

c. Wind rate in the room of integrative curing / drying is adjusted by frequency converter

which can ensure the most reasonable circulating air during curing stage and drying stage.

d. It adopts humiture-integrated transducer. It bears high temperature and humidity and its meters wear well.

e. The control on temperature and humidity is totally automatic. It can ensure the effect of plate curing and drying, and avoid the impact of human factors.

f. Excellent structural design could ensure the temperature, humidity and airflow in the room to be well distributed and reasonable.

g. Effective curing and drying will save energy and time.

h. The processing parameters, such as the values temperature and humidity and time, can be freely set into different stages during the course of curing.

Main technical parameters:

Space of room: 30~60m³

Room temperature: ~80℃, precision: ±2%

Humidity: ~100%RH, precision: ±3%

Circulating air: 3000m3/h~18000m3/h

Power of fan: 3kw~11kw

Pressure of compressed air: 0.6Mpa~0.7Mpa