Favor

Favor

Lithium battery charging and discharging motor

- CB30 Fully Automatic 3-head-5-spot Intercell Welding Machine

- QM10 Automatic Air Leakage Tester

- SGH20B Epoxy Seal Curing Machine

- DL20 High-voltage Pulse Plate Short Circuit Tester

- BP-12 Fully Automatic Plate Enveloping Machine

- ZH-20 Fully Automatic Cast-On-Strap Machine

- GHY30 tunnel plate curing drying chamber

- GH20 Brick Wall-type Curing & Drying Chamber

- GH30 Integrative Plate Curing & Drying Chamber

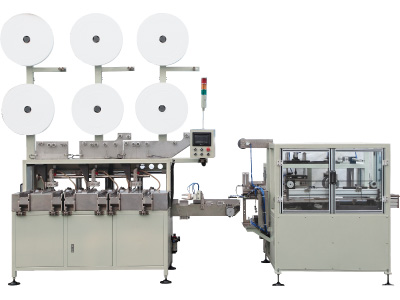

- QF500C/1000C Series Fully Automatic Lead Oxide Production Line

- QFZ Series Fully Automatic Lead Oxide Ball Mill

- JFTD Series Auto Testing Equipment for Li EV Battery, Battery Pack

- JFAD Series Auto Testing /Formation/Grading Equipment for Li EV Battery

- JFA Series Li Battery Formation,Grading, Testing Equipment

- μC-DF08 Microprocessor-controlled Battery's Capacity&Discharging Performance Tester

- μC-ZS08 Microprocessor-controlled Battery's Multiple Parameters Tester

- μC-XCF08 Microprocessor-controlled Battery Cycling Charge/Discharge Lifetime Tester

- μC-KGCFS/KGCFSH Intelligent Plate Formation Charger/Discharger

- μC-3000GHA Green Plate Formation Charger/Discharger

- μC-MKCF/MKCFA Pulse Fast-speed Formation Charger/Discharger

- μC-2000S/KGCFS/KGCFSH Intelligent Battery Formation Charger/Discharger

- μC-3000GH、GHA Battery Formation Charger/Discharger

- μC-CFXF Integrated Machine for Data Logger and Battery Sorting

- μC-MKCF/MKCFA Pulse Fast-speed Formation Charger/Discharger

- μC-3000S/3000SH Fully Digital Battery Formation Charger/Discharger

- μC-3000GS、GSA Bus-bar Type Battery Formation Charger/Discharger

- μC-3000GH/GHA Bus-bar Type Battery Formation Charger/Discharger

Application:

For lead oxide production and red lead oxide production

Functions & Features:

1. This machine is a fully automatic, high-efficiency and energy-saving lead oxide production line, which having the advantages of small area occupied, high apparent density, easy control and so on. Barton type lead oxide mill produce lead oxide with gas phase oxidation method, which has the different working principle with Shimadzu ball mill. 2. Batteries which made by the lead oxide produced from the barton oxide mill has the advantage of long cycle life, the machine mainly using for traction-type, fixed type and other deep discharging batteries. Also this is the preferred machine for red lead oxide production 3. By the way of automatic constant-current control the quantity of lead oxide in reaction pot to filling the lead liquid automatically. 4. PLC touch screen with fully automatic control, timely displaying operation status and parameters of each unit ,and automatically recording , as well as displaying alarming for malfunction and solving the problems. 5. Exhaust gas is treated by high-efficient dust collector, so it accords with the requirements of Environmental standards.

Technical Parameters:

1. Oxidization Degree: For battery making lead oxide 70~82% ( For red lead powder can be over 95%)

2. Apparent Density: 1.4~1.8g/cm³

3. Acid-absorption: 160~190mg/g

4. Capacity: 12~15T/D

5. Screenings: ≤2%( screen mesh 100)