Favor

Favor

Lithium battery charging and discharging motor

- CB30 Fully Automatic 3-head-5-spot Intercell Welding Machine

- QM10 Automatic Air Leakage Tester

- SGH20B Epoxy Seal Curing Machine

- DL20 High-voltage Pulse Plate Short Circuit Tester

- BP-12 Fully Automatic Plate Enveloping Machine

- ZH-20 Fully Automatic Cast-On-Strap Machine

- GHY30 tunnel plate curing drying chamber

- GH20 Brick Wall-type Curing & Drying Chamber

- GH30 Integrative Plate Curing & Drying Chamber

- QF-15B Barton Type Lead Oxide Mill

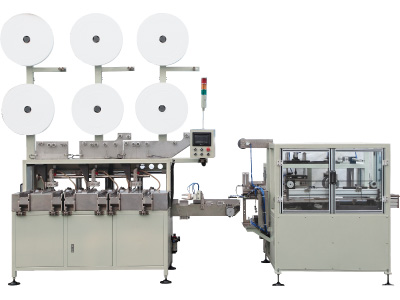

- QF500C/1000C Series Fully Automatic Lead Oxide Production Line

- JFTD Series Auto Testing Equipment for Li EV Battery, Battery Pack

- JFAD Series Auto Testing /Formation/Grading Equipment for Li EV Battery

- JFA Series Li Battery Formation,Grading, Testing Equipment

- μC-DF08 Microprocessor-controlled Battery's Capacity&Discharging Performance Tester

- μC-ZS08 Microprocessor-controlled Battery's Multiple Parameters Tester

- μC-XCF08 Microprocessor-controlled Battery Cycling Charge/Discharge Lifetime Tester

- μC-KGCFS/KGCFSH Intelligent Plate Formation Charger/Discharger

- μC-3000GHA Green Plate Formation Charger/Discharger

- μC-MKCF/MKCFA Pulse Fast-speed Formation Charger/Discharger

- μC-2000S/KGCFS/KGCFSH Intelligent Battery Formation Charger/Discharger

- μC-3000GH、GHA Battery Formation Charger/Discharger

- μC-CFXF Integrated Machine for Data Logger and Battery Sorting

- μC-MKCF/MKCFA Pulse Fast-speed Formation Charger/Discharger

- μC-3000S/3000SH Fully Digital Battery Formation Charger/Discharger

- μC-3000GS、GSA Bus-bar Type Battery Formation Charger/Discharger

- μC-3000GH/GHA Bus-bar Type Battery Formation Charger/Discharger

Application:

For lead oxide production;

Functions & Features:

1. This line is the new generation of High-efficient & Energy-saved lead oxide production line, which absorbs the experience of advanced lead oxide manufacturing technology home and abroad and adds our own technology innovation, having the advantages of stable physical & chemical index, low consumption, high capacity and so on, is the ideal selection for lead oxide manufacturing;

2. Main unit adopts weighing way, lead ball is kept with same weight by PLC control;

3. It adopts water cooling in the drum, non-positive-pressure blowing system, to realize low consumption for main unit and high efficiency for lead oxide production;

4. It is equipped with special pre-heat system. Air flow will be adopted the pre-heated interlining air between drum and enclosure, it can get the stable lead oxidization though it changes too much of ambient temperature

5. PLC touch screen with fully automatic control, timely displaying operation status & parameters of each unit, and automatically recording, as well as displaying alarming for malfunction and solving the problems.

6. It has high precision control of lead ball quantity, negative-pressure, temperature and so on, and has stable physical & chemical index;

7. Exhaust gas shall be treated by high-efficient dust collector, so it meets the National Discharge Standard;

Technical Parameters:

1. Apparent Density: 1.2~1.5g/cm3

2. Oxidization Degree: 70%-80%

3. Acid-absorption: 220-280mg/g

4. Screenings: ≤1% (screen mesh 100)

Specifications:

| Models | Control Method | Air Control Method | Cooling Method | Rotational Method | Main Unit Power | Capacity (Day) |

| QFZ-14S | Weight | Negative | External Water Spraying | Chain Wheel | 75Kw | 14T/D |

| QFZ-24S | Weight | Negative | External Water Spraying | Chain Wheel | 132Kw | 24T/D |