Favor

Favor

cylindrical, soft pack, square lithium battery cell middle section equipment, rear section module pack equipment, chemical composition and capacity aging equipment, warehouse logistics system, MES, power supply, testing, software development, etc

- Cutting and Stacking Machine

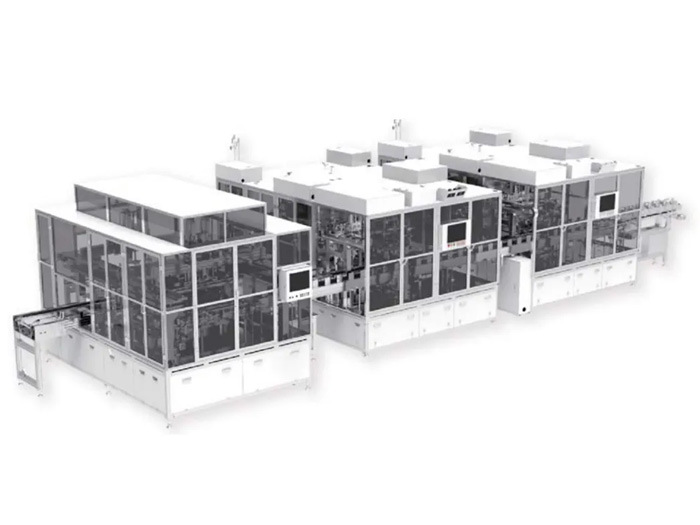

- Automatic Pouch Battery Module Pack Assembly Line

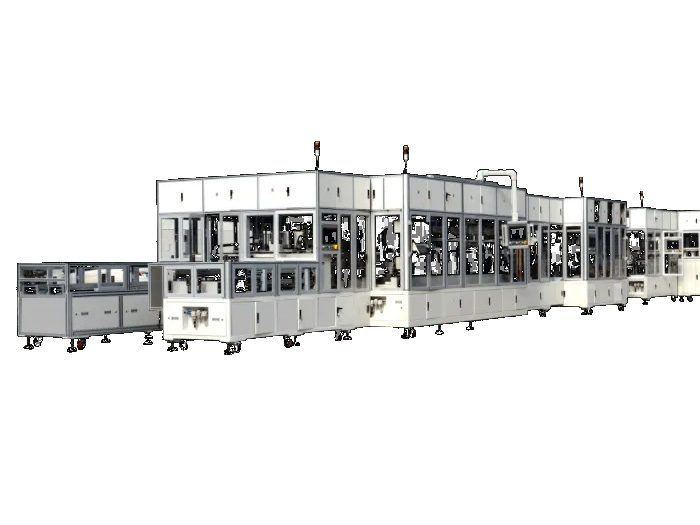

- Automatic Cylindrical Battery Module Pack Assembly Line

- Automatic Vacuum Infusion Machine for Pouch Lithium Batteries

- Automatic Battery Formation & Capacity Grading Line

- Laser Pelleter Machine

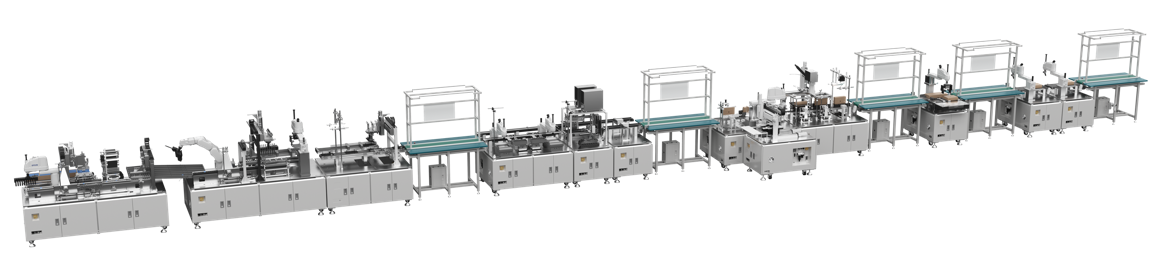

- Battery Cell Assembly Line

- 圆柱电池模组PACK组装线

- 方形铝壳储能模组PACK组装线

- 方形铝壳储能模组PACK组装线

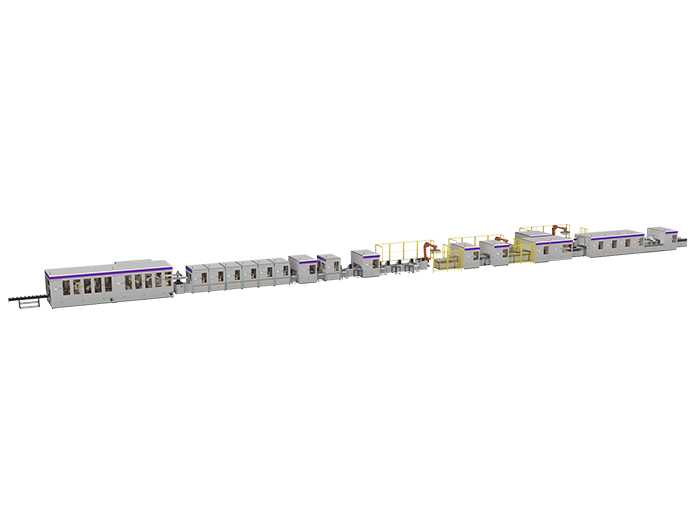

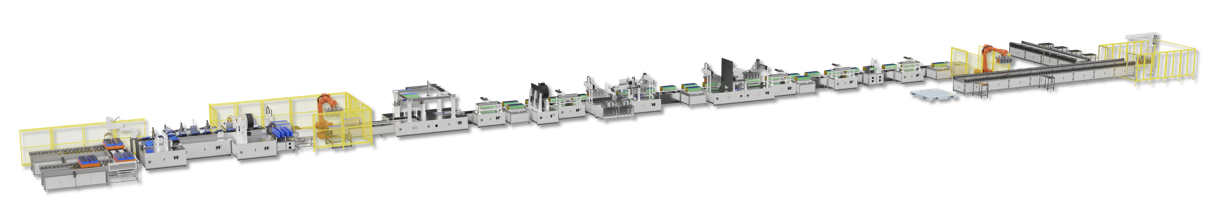

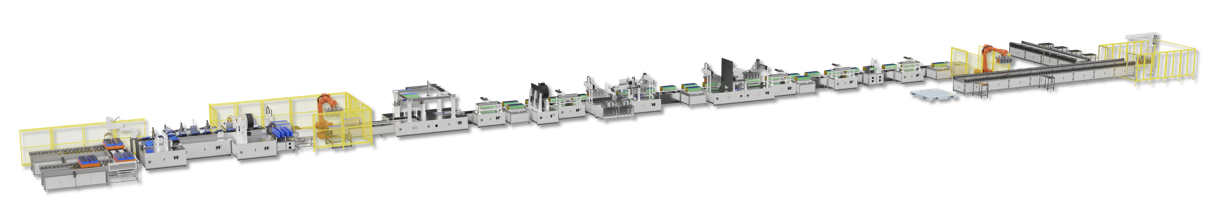

- 圆柱电池多功能数码一体机

The Automatic Prismatic Battery Module Pack Assembly Line consists of cell loading line & OCV test, plasma cleaning, battery gluer, component pre-stacking, module stacking + robot loading and unloading, end plate & side plate & epoxy board loading & unloading & gluing, module molding Strip, steel strip, module end plate laser coding, module static & module heating and pressurization, cell safety test, pole addressing & pole laser cleaning & manual busbar assembly, busbar laser welding Weld seam cleaning after machine and module welding, visual inspection after module busbar welding, insulation test after module welding, manual installation of protective cover + manual labeling & PIN needle visual inspection machine & size visual inspection machine, weighing & module Offline and other equipment components.

Cell application range: L90-250*W80-350*T20-100(mm)

Module application range: L650*W500*H500(mm)

Production Line Dimension: L77000*W4000*H2600(mm)

Production Line Efficiency: 20ppm