Favor

Favor

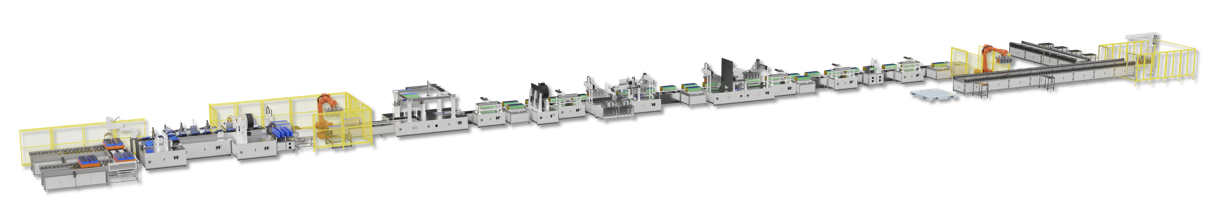

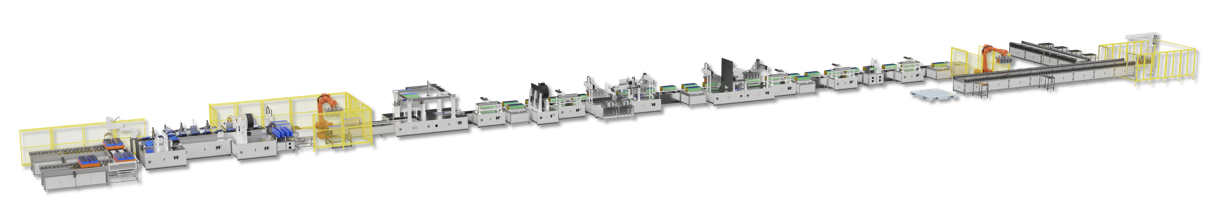

cylindrical, soft pack, square lithium battery cell middle section equipment, rear section module pack equipment, chemical composition and capacity aging equipment, warehouse logistics system, MES, power supply, testing, software development, etc

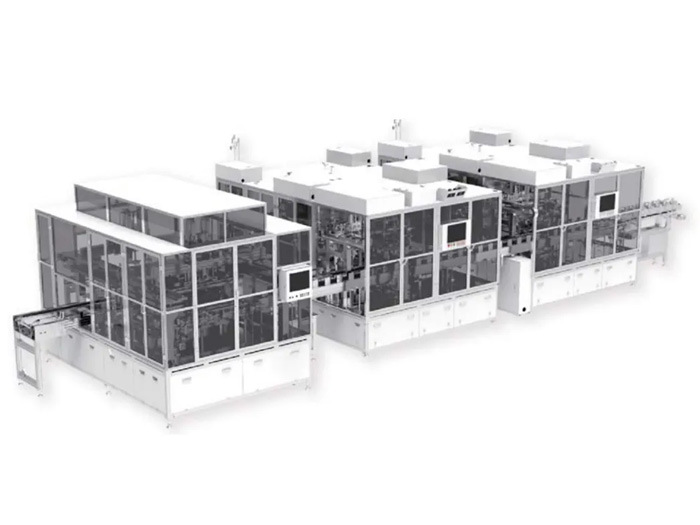

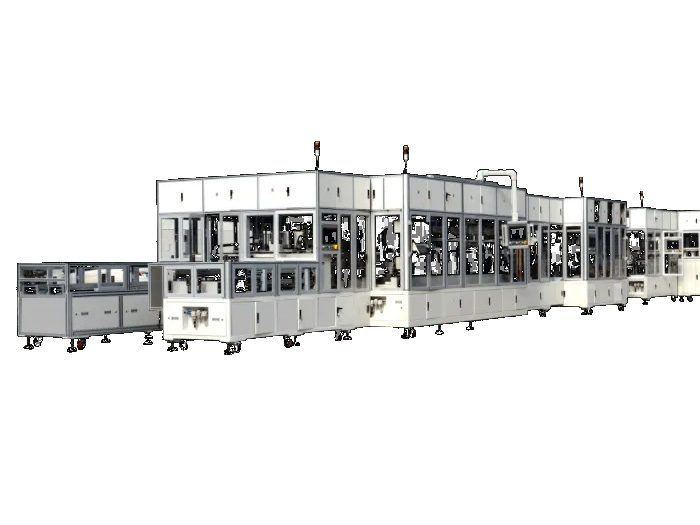

- Automatic Prismatic Battery Module Pack Assembly Line

- Automatic Pouch Battery Module Pack Assembly Line

- Automatic Cylindrical Battery Module Pack Assembly Line

- Automatic Vacuum Infusion Machine for Pouch Lithium Batteries

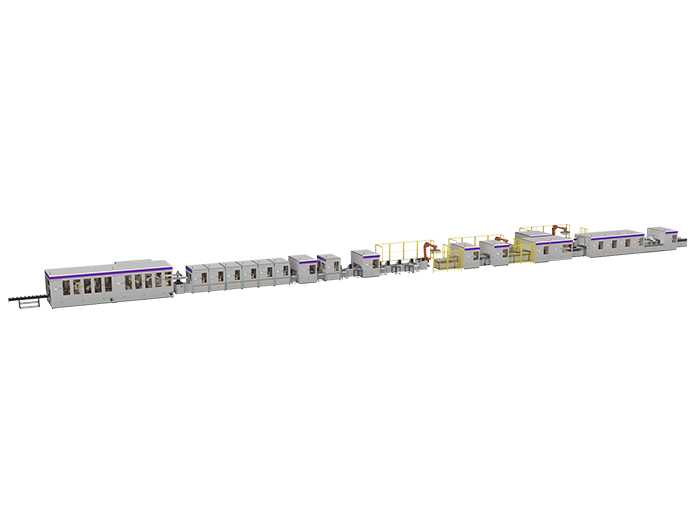

- Automatic Battery Formation & Capacity Grading Line

- Laser Pelleter Machine

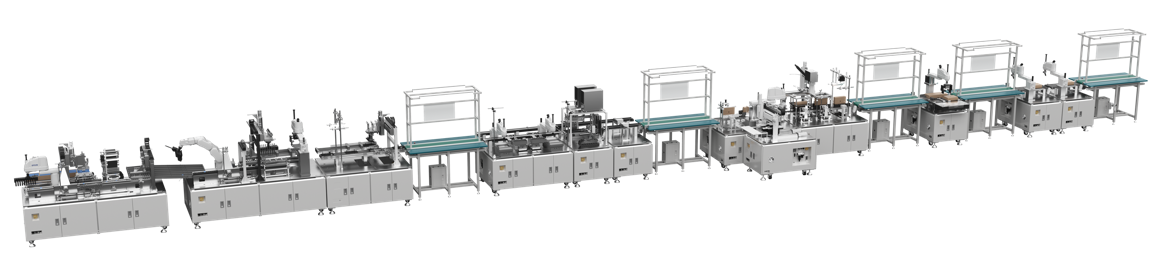

- Battery Cell Assembly Line

- 圆柱电池模组PACK组装线

- 方形铝壳储能模组PACK组装线

- 方形铝壳储能模组PACK组装线

- 圆柱电池多功能数码一体机

The design and layout of the whole machine are reasonable. The stacking table and glue are located on both sides of the pole piece feeding mechanism, which is convenient for the maintenance of the whole machine and the feeding of auxiliary materials;

The cycle continuous feeding method is adopted, and the blockage of the non-electrode sheet conveying ensures the equal beat of each stacking stage

The circular transportation line guarantees no waste, no waste pieces, and improves the utilization rate of pole pieces;

The adaptability of the pole piece is strong, which avoids the problem that the vacuum belt transmission cannot be used due to the change of the pole piece size;

The pole piece transportation line is more stable than the vacuum belt, which avoids the problem of grabbing misalignment and grabbing damage to the pole piece by the vacuum belt method;

Integrated functions: This machine can integrate pole piece size and defect detection, pole piece powder brushing function, battery hot pressing, battery short circuit test and other functions,

Laminated CCD visual positioning system, servo motor + precision ball screw positioning movement, precise X, Y, @ positioning, high stability;

The diaphragm is automatically unwound to improve the utilization rate of the whole machine;

Separate control of dust generated by the whole machine: such as unwinding, an independent area, a die-cutting area, and work in the area where more dust is generated, no waiting phenomenon, high efficiency.

1. Improve the utilization rate of the whole machine;

2. Die-cutting area is added with FFU to extract the floating powder of the environment, (die-cutting area) is added with FFU to extract the floating powder of the environment;

3. Die-cutting efficiency: 300pcs/min; lamination efficiency: 0.45s/pcs