Favor

Favor

cylindrical, soft pack, square lithium battery cell middle section equipment, rear section module pack equipment, chemical composition and capacity aging equipment, warehouse logistics system, MES, power supply, testing, software development, etc

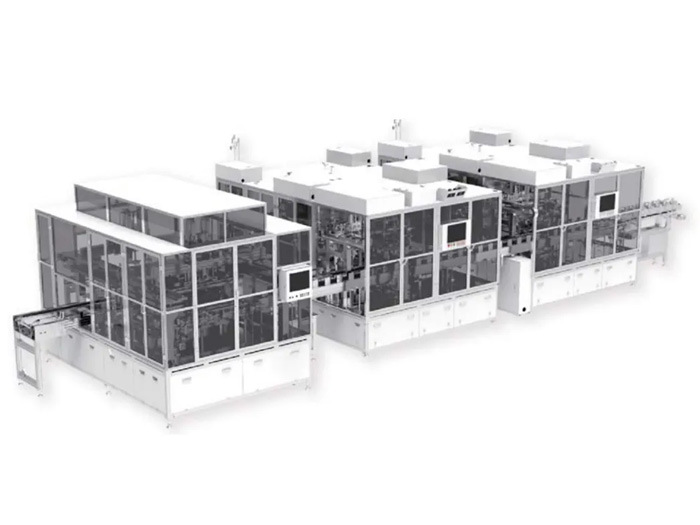

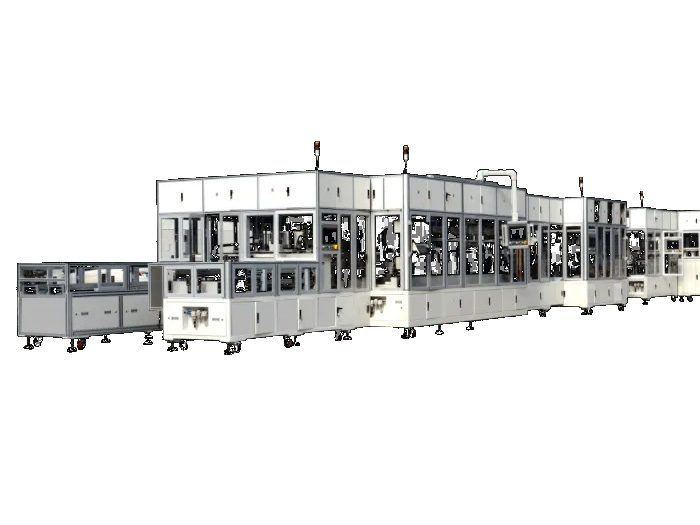

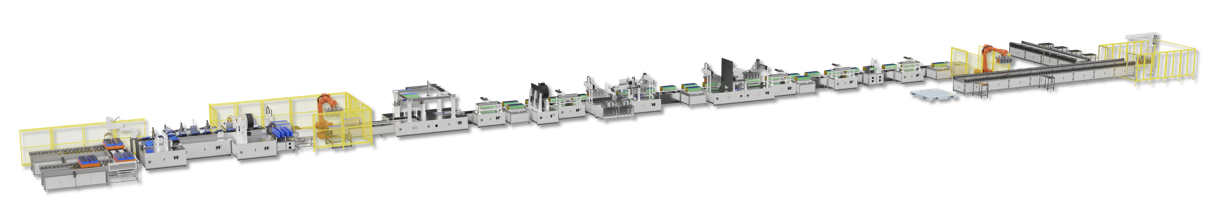

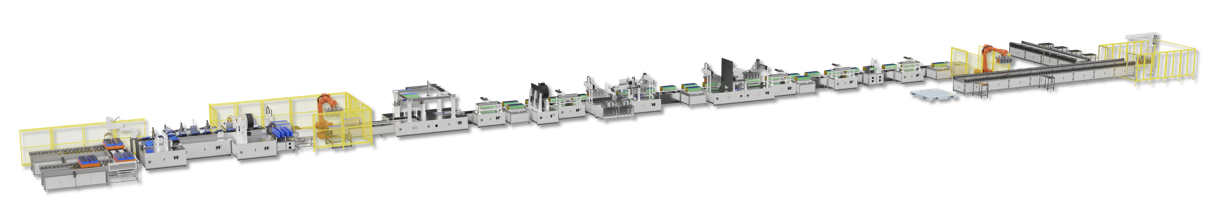

- Automatic Prismatic Battery Module Pack Assembly Line

- Cutting and Stacking Machine

- Automatic Pouch Battery Module Pack Assembly Line

- Automatic Cylindrical Battery Module Pack Assembly Line

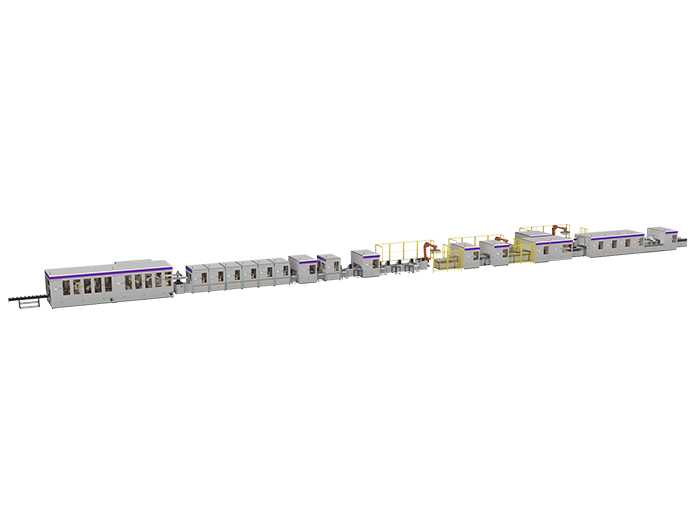

- Automatic Battery Formation & Capacity Grading Line

- Laser Pelleter Machine

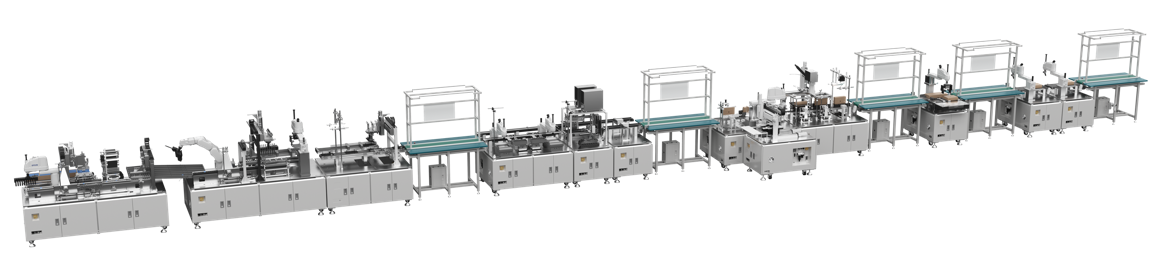

- Battery Cell Assembly Line

- 圆柱电池模组PACK组装线

- 方形铝壳储能模组PACK组装线

- 方形铝壳储能模组PACK组装线

- 圆柱电池多功能数码一体机

Functional Overview:

It is mainly used for automatic liquid injection, evacuation and pre-packaging of soft-pack liquid lithium-ion batteries. Realize automatic code scanning, weighing, liquid injection, vacuum standing for three times, vacuum sealing, and weighing after liquid injection for soft-packed lithium-ion batteries before liquid injection, sorting NG cells, and good-quality cells are output from the material box.

Technical Features:

● Automatic product scanning and weighing before liquid injection.

● The product automatically injects liquid in vacuum and stands still in vacuum.

● The product is automatically vacuum pre-sealed.

● Automatic weighing and NG sorting after liquid injection.

● The liquid injection pump and the control box are isolated from the equipment separately to facilitate parameter adjustment and avoid pollution and corrosion.

● Product injection and good product automatic material box output.

● The liquid injection station adopts liquid injection under vacuum state to ensure that the electrolyte can quickly penetrate into the cell.

● The product fixture circulation device is equipped with a liquid tank to prevent the residual electrolyte on the product positioning device from polluting and corroding the equipment.

● Automatic electrolyte stirring system to remove air bubbles and prevent dripping during liquid injection.

● The structure of the head assembly adopts the opening and closing movement structure, which is convenient for inspection, maintenance and assembly.