Favor

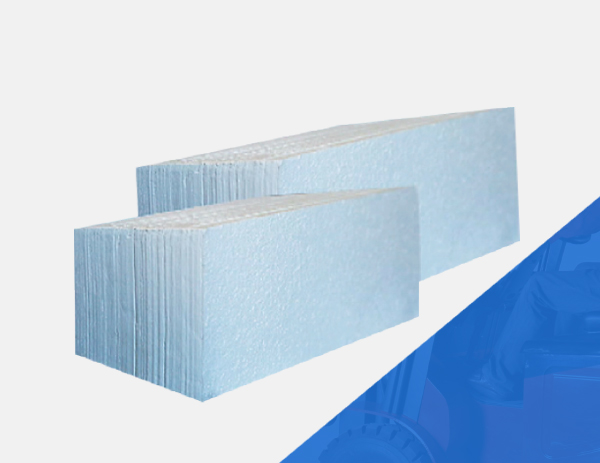

Favor - Lead carbon battery AGM separator

- High temperature resistant battery AGM separator

- Traction type battery AGM separator

- Power battery AGM separator

- Fixed storage battery AGM separator

- AGM Separator for start-stop battery

- Energy storage battery AGM separator

- New energy vehicle battery AGM partition

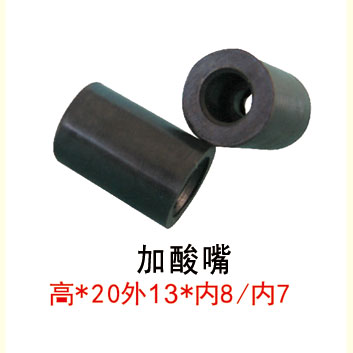

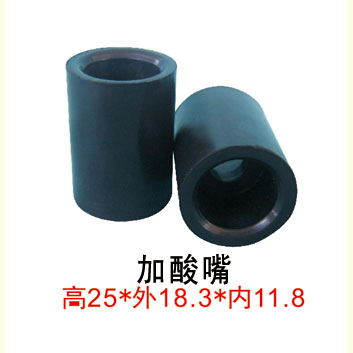

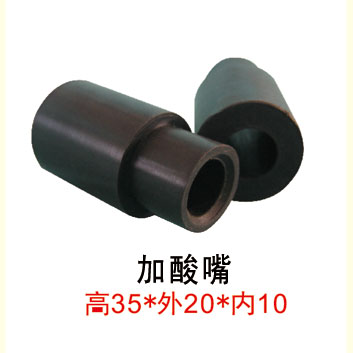

- 加酸嘴

- 加酸嘴

- 加酸嘴

- 加酸嘴

- 加酸嘴

- 加酸嘴

- 加酸嘴

- 加酸嘴

- 加酸嘴

- 加酸嘴

- 加酸嘴

- 加酸嘴

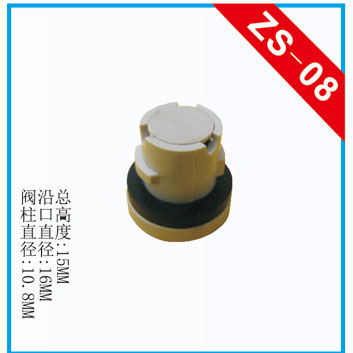

- 分体阀

- 分体阀

- 分体阀

- 分体阀

- 分体阀

- 分体阀

- 分体阀

- 分体阀

- 分体阀

- 分体阀

- 分体阀

- 分体阀

- 分体阀

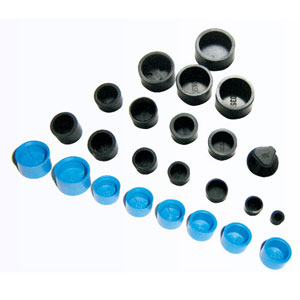

- 端子套

- 端子套

- 端子套

- 端子套

- 端子套

- 端子套

- 端子套

- 端子套

- 端子套

- 端子套

- 端子套

- 端子套

- 端子套

- 端子套

- 端子套

- 端子套

- 端子套

- 端子套

- 端子套

- 端子套

- 端子保护帽

- 胶帽

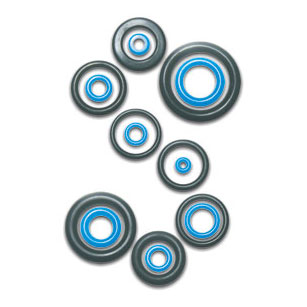

- O型圈

- O型圈

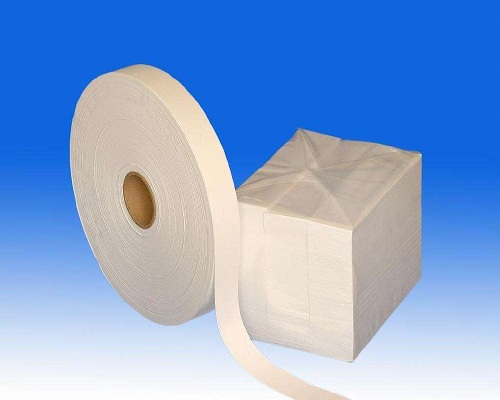

- AGM separator

- AGM separator

- AGM separator

- AGM separator

- AGM separator

- AGM separator

- AGM separator

- AGM separator

- AGM separator

Battery production technology continues to improve, production mode continuous production, mesh, continuous casting, continuous pressing, continuous punching and other continuous plate grid production technology. The main purpose of the coated board paper is to attach to both sides of the plate when the plate is coated, to prevent lead from sticking to the equipment, and to prevent the plate from sticking together when stacked. With the protection of coated board paper, dust can be greatly reduced in the process of plate transportation and assembly, which is conducive to environmental protection. Moreover, the performance of AGM coated board paper in the process of battery formation is the same as that of AGM separator (coated board paper of other materials will have a certain impact on the battery performance when it is contained in the electrolyte during the use of battery), with good strength, acid resistance and corrosion resistance. The battery performance is not affected.

| Index | |||||

|---|---|---|---|---|---|

| Thickness tolerance(mm) | ±5% | Basic weight(g/㎡mm) | 150±5%(20Kpa) | Strength(KN/m) | ≥0.6d |

| Resilience(%) | ≥94 | Acid wicking g/g | ≥8.5(0Kpa) | Resistance(Ωd㎡/mm) | ≤0.0005 |

| Water content(%) | ≤0.5 | Porosity(%) | ≥90 | Climb acid height | ≥85(mm/5min) |

| Iron(%) | ≤0.003 | Acid loss weight(%) | ≤3.0 | Loss ignition(%) | ≤1.0 |

| Chlorine(%) | ≤0.003 | ||||