Favor

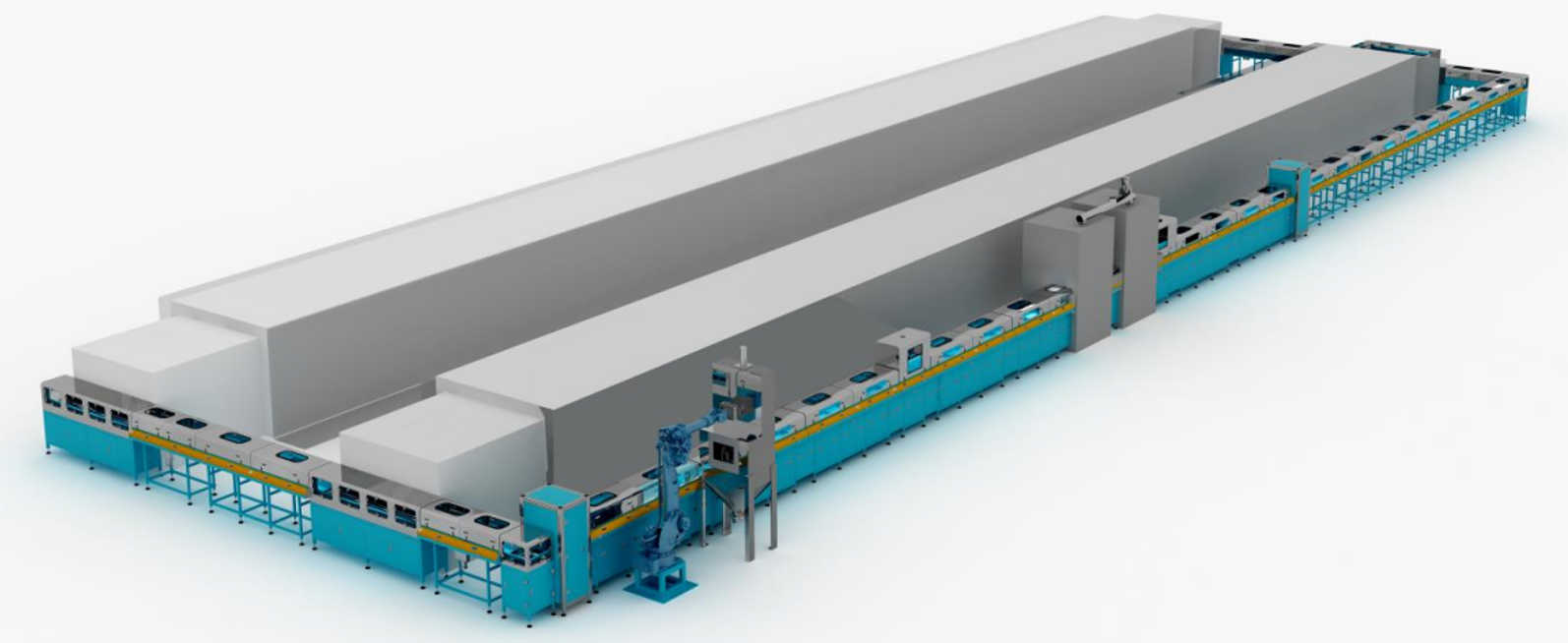

Favor | Item | RHK |

| Loading Capacity | 6-row double-stack |

| Sagger size | 330*330*140 |

| Temperature | <800℃ |

| Length | 60m |

| Atmosphere Protection | Nitrogen |

| Structure | Arch roof for heating section and flat roof for heat preservation |

Technical features:

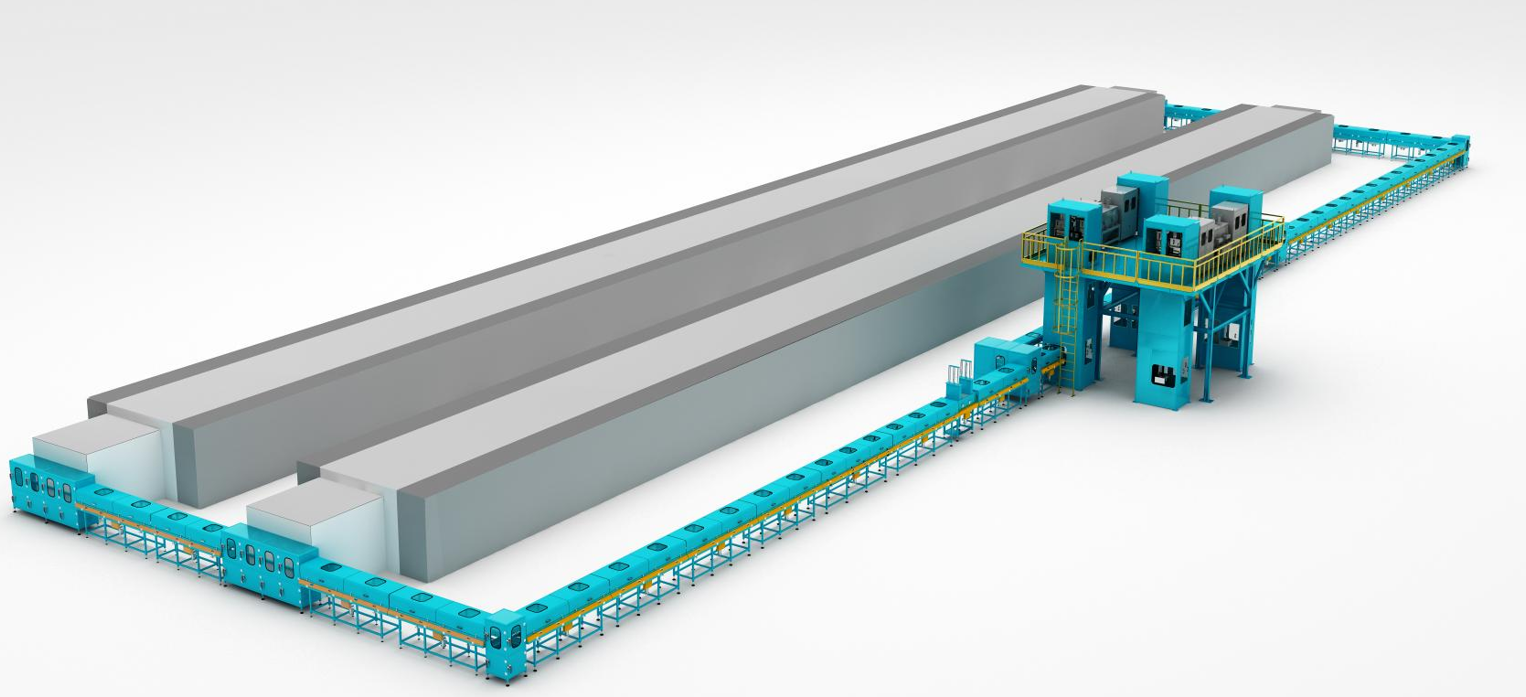

Thanks to good atmosphere and temperature distribution, cleaner kiln environment, as well as multi-chamber and ultra-long kiln body design, the product features more production capacity, lower unit energy consumption, and an automatic loading/unloading system.

1. High gas-tight design: The sealing of roller drive part is enhanced while that of furnace body is optimized. .

2. Transmission stability design: Universal joint, safety pin, and broken roller detection.

3. Atmosphere uniformity improvement design: Increased temperature of both sides of sagger and materials, reduced temperature difference between the sections, and improved temperature uniformity.

4. Use of low energy consumption materials: The newly-used block (Pyro-Block) has low heat transfer rate, which can reduce heat loss and lower the surface temperature by 5-10℃.

5. Optimized exhaust emission: Gas exhaust structure, industrial burner, and exhaust gas heat exchange tube.