Favor

Favor

Battery manufacturing equipment, lead-acid batteries, lithium batteries, accessories,, raw materials

- Battery Charging And Discharging Machine

- Battery Acid Filling Machine

- Battery Marking Machine

- Plate Short Circuit Testing Machine

- Plate Enveloping And Stacking Machine(PE)

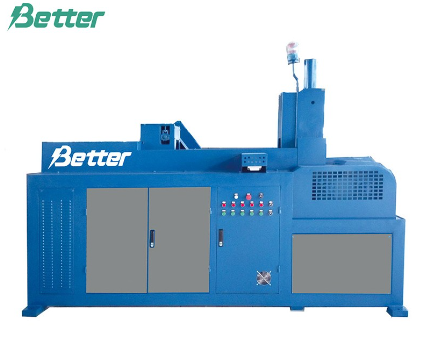

- Lead ingot cold cutting machine

- Plate Charging Machine

- Plate Charging Bath

- Plate Brushing Machine

- Battery Plate Cutting Machine

- battery plate curing and drying chamber

- Plate Flash Drying Oven

- Double Sides Pasting Machine

- Lead Paste Mixing Machine

- Plate formation charger and discharger

- Tubular Battery Plate PDC Machine

- Lead Oxide Filling Machine

- Lead Oxide ball mill Manufacturing Machine

- Mould

- Pasting Shoe

- Pasting Shoe

- Plate Formation Tank

- lead dross remover agent

- Mould

- DM Water Plant

- Acid Pot

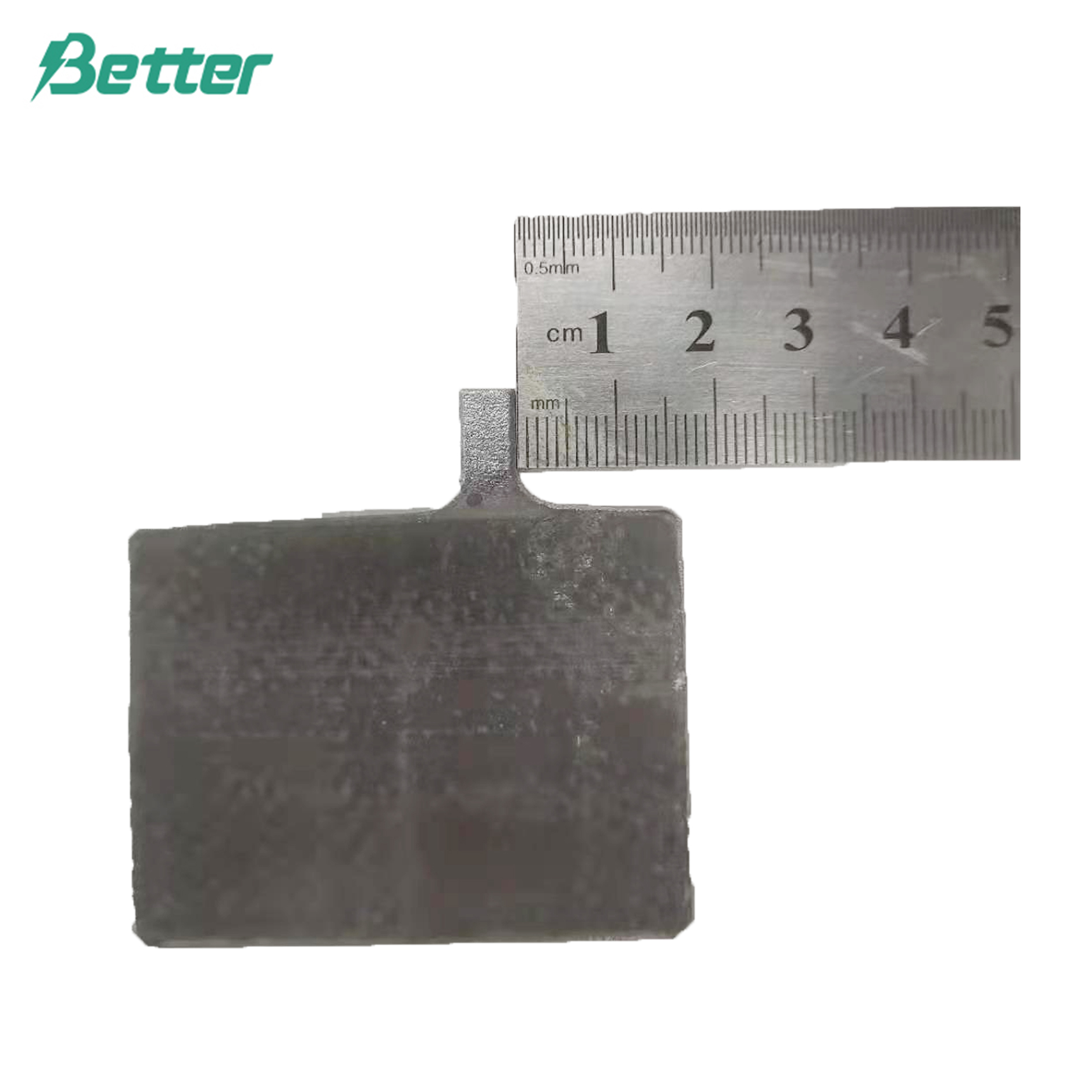

- Battery Plate

- Battery Terminal

- Mold dope

- Red lead

- Sticker

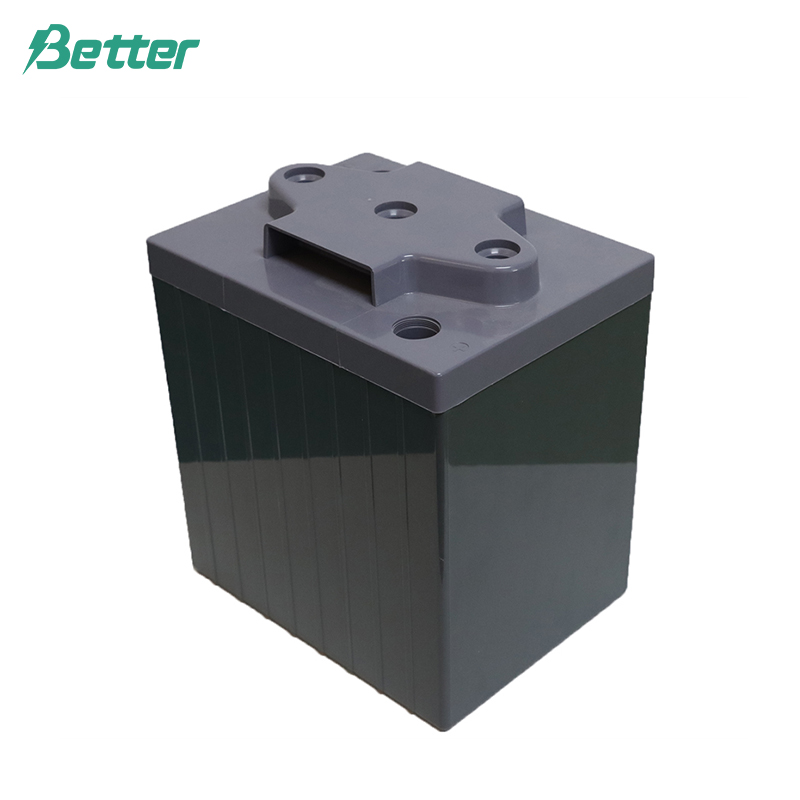

- 2V Battery container

- Acid botter

- Automotive battery container

- Battery Container

- Epoxy

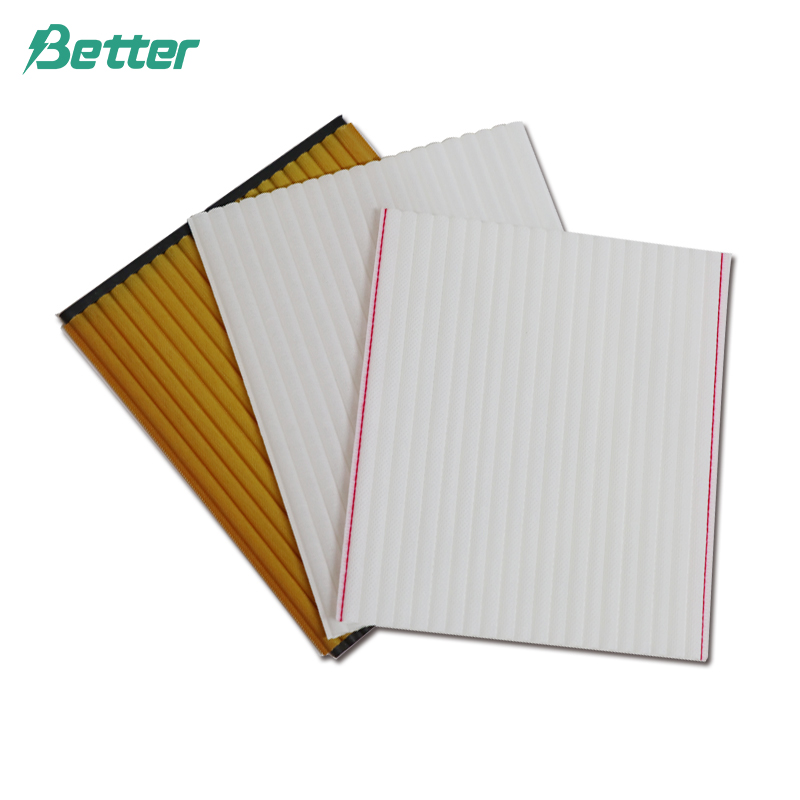

- Battery Separator

- pasting paper

- Pad

- Battery Safety Valve & O-ring

- Epoxy mixing tube

- Heat Sealing Mould

- Casting flux

- Manual Small Parts Mould

- Plate formation jar

- Plate Group Welding Mould

- Pole Welding Mould

- Flame arrester

- Gauntlet

- Wrapping film

- Injection Mould

- Casting Mould

- Small Parts Casting Mould

- Lead terminal

- Motorcycle battery container

- Heating Tube

- FRP GRILLE

- Turnove box

- Brush wheel

- Roller cutter

- Pasting Belt

- E-bike Assemble SeriesSmall VRLA Welding Mould

- PET film

- aluminum foil

- Battery pallet

- Grid Punching Mould

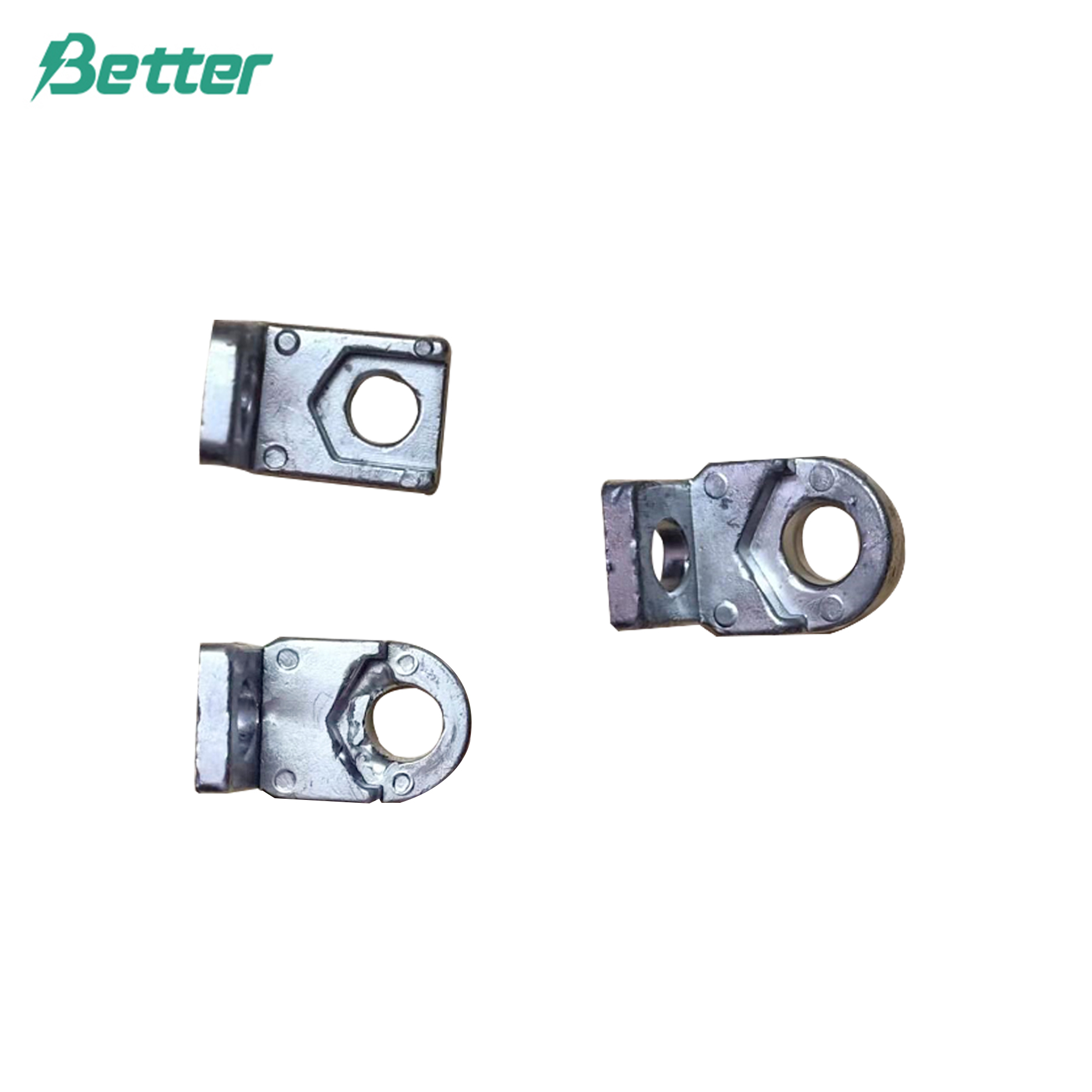

- Terminal of motorcycle battery

- Plate of motorcycle battey

- 6V Battery container

- Battery charging and discharging motor

- PE包板机

- 合膏机

1. Introduction

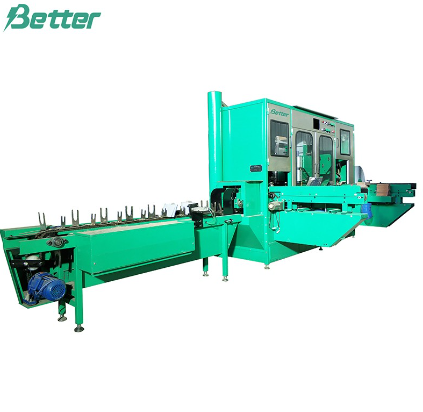

The tunnel plate dying oven is used for drying of the negative or positive plates after plate formation and plate washing process. As per requirement, the consuming resources could be gas burning or electrical heating.

The transmission type of plates could be tank chain and string roller chain, the new string roller chain transmission is suggested.

Plate collector types are vertically collecting (suitable for plate thicker than 1.2mm) and horizontal collecting (suitable for plates thinner than 1.2mm).

2. Main Technical Parameters

2.1 Main transmission

Main drive: power 2.2KW; cycloid reducer adopts frequency control;

Chain speed: 0.5~1.4m/min

2.2 Hot air circulation blower (3pcs)

Power 7.5KW × 3; air volume Q = 1.3m3/h; whole pressure: 1000Pa.

2.3 Waste exhaust blower: (3pcs)

Power: 1.1Kw×3

Wind amount: 3710M3/h

Full wind pressure: 333Pa

2.4 Drying oven temperature: range: 80~150℃ (Temperature in each section can be individually set)

2.5 Dimension

Outer dimensions: 22500 (L)* 1520(W)* 2385(H), Length includes: front frame: 2000mm, drying box: 18000mm, rear frame: 2500mm

2.6 Total weight: 5.7 Tons

2.7 Electricity power: 180Kw (3 groups, first section is 84Kw, second section is 60Kw, third section is 36Kw)

2.8 Air conduct

We only provide air suction blower, the user has to prepare the pipeline; please do install the outlet of air to the outdoor.