Favor

Favor

packing machine

- Ultrafine barium sulfate

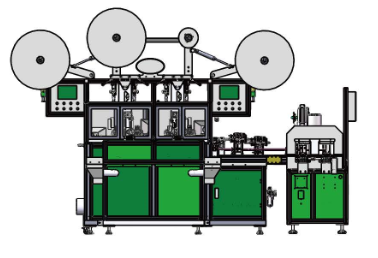

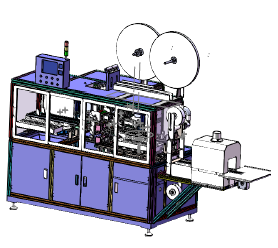

- Automatic PE Enveloping Machine for Car Batteries with Group

- Automatic AGM Enveloping Machine For Small Batteries

- Auto AGM Enveloping Machine For Super Small Batteries

- Auto AGM Enveloping Machine For Medium Size Batteries

- Automatic AGM Enveloping Machine For Big Batteries

- Automatic AGM Enveloping Machine For 2V Batteries

- Automatic AGM Enveloping Machine With Side Separaror /Negative Plate

- 2V Automatic battery plate packing machine

- Automatic mid&large-capacity battery

- Automatic small-capacity battery

- Automatic micro-capacity battery

- Automatic motorcycle battery PE bag packaging assembly machine

- Automatic automobile battery envelper&stacker

- Full-automatic safety valve capping machine

- Automatic PE bag automobile battery plate packing machine

- Automatic mid-capacity battery

User set the length of PE separator. The machine automatic feeding plate and PE, automatic enveloping PE bag and enveloping plate, .

Application:

Apply to enveloping plates for car batteries, Such as 12V45Ah,65Ah,80Ah etc…

Functional characteristics:

Ø PLC control system, touchable the man-machine interface.

Ø Single feeding rack, feeding motor worked automatically according to the detection of photoelectric signal, automatic feeding.

Ø Set the length of PE follow plat’s size, the machine Automatic measuring PE’s length and automatic cutting.

Ø The cutting position can be adjusted up & down, change mould for center line of PE Separator

Ø According to the size of the plate, the width of the horizontal transfer track can be adjusted; According to the width of the PE, the width of the PE transfer track can be adjusted; Model change can be completed within 15 minutes, especially suitable for multi-specification battery enveloping plate in one machine.

Ø The machine is equipped with two sets suction plate system, 2 set Positive conveyor adopts parallel feeding, feeding balance, stability, neat, lack of plate alarm.

Ø Set the number of positive plates and negative plates freely, Such as 2+/2- ,3+/3-.......8+/8- etc…; The plate group conveying adopts the non-slip chain transmission with fill group alarm on the conveyor.

Ø Fully closed design, exhaust system in the lower part of the machine, Can better to collecting lead dust and effective protection electronic components.

Ø The machine is equipped with automatic alarm security system, and meet safety gate was opened, the machine automatic stop.

Ø The equipment is equipped with centrifugal pump suction plate system with dust filter, It can be removed and cleaned; The machine has suction plate detection function.

Ø The machine is equipped with automatic alarm security system, and meet the alarm, will automatically alert, and automatic stop immediately and display the alarm information on the man-machine interface; The machine is equipped with functional button switches such as start, stop and reset etc….

Ø The machine is equipped with automatic mode and Manual mode etc…

Ø The machine can automatically record the effective working time, failure time, failure times and qty.

Ø Users can choose left - out models or right - out models according to the production line.

Technical parameters:

Ø Input:3 phase 380Vac /50Hz

Ø Air Supply:0.6~0.8MPa

Ø Power: ≦3.5KW

Ø Efficiency: more than 90%

Ø Separator: PE

Ø Capacity: 80PCS/min

Ø Rejection rate:≦5‰(Plate don't has deformation, holes, cracks, model change and equipment not normal maintenance except)