The company is located in The Economic development Zone of Changxing County, Zhejiang Province, covering an area of about 97.8 mu, with a construction area of about 70,000 square meters. It is the professional manufacturer of lead acid battery equipment with the strongest comprehensive strength in China.

Over the years, the company focuses on the development of lead-acid battery automation equipment, has experienced battery automation equipment technical personnel and high-quality staff. In 2011, the company won the honorary title of "high-tech Enterprise", in 2012, the company was awarded as Zhejiang Province patent Demonstration enterprise. The fully automatic casting and welding machine independently developed by the company fills in the blank of lead-acid battery industry, eliminates decades of labor-intensive manual welding process in China, improves production efficiency, reduces labor force (reducing the production personnel in the front section to 45%-50% of the original), and reduces the direct contact between operators and lead components. While protecting workers' health to the greatest extent, it also reduces lead pollution in the environment to the greatest extent.

At present, the company has 165 customers, the main customers include Tianeng Power, SUPER Power, Narada Power and Lisi International and other domestic and foreign listed enterprises. Into 2302, our company large and dense automatic casting and welding machine, automatic coating machine and automatic dispensing machine has been successfully developed. Company formed zhejiang haiyue robot co., LTD. At the same time, automation equipment and industrial robots and effective integration, built the cuhk dense lead battery intelligent manufacturing integration ", "the little secret lead battery intelligent manufacturing integration solutions" to the market in succession, for the product, do strong, do big, do to do the main supplier of the global automation equipment.

More Products >

.jpg)

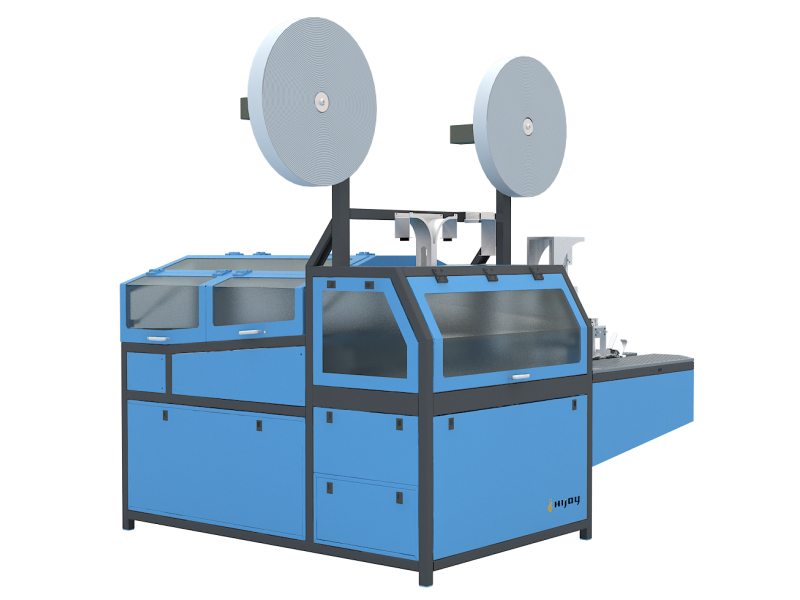

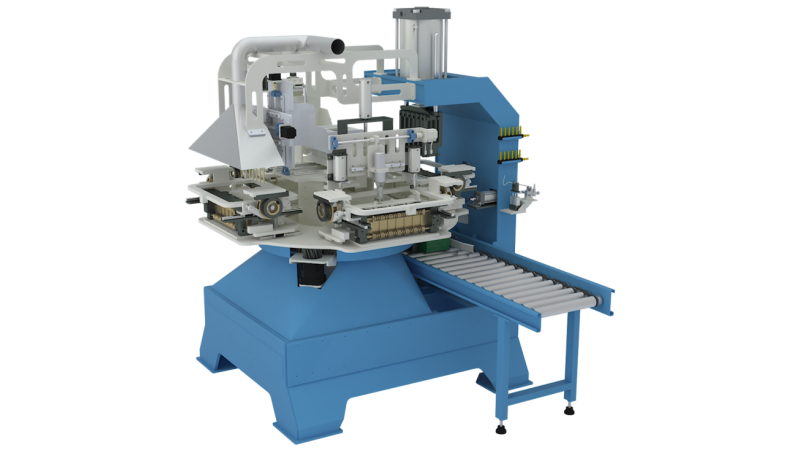

E(production ):AC220V@50HZ; 1KW(max).

applicable grid range: take negative plate for example, an additional of 1-1.3 seconds are required for an extra unit of negative electrode. (single shift productivity is 600-700 20AH batteries or 480-550 batteries 12AH batteries)

type(separator paper ):

Number(matched pieces):

.jpg)

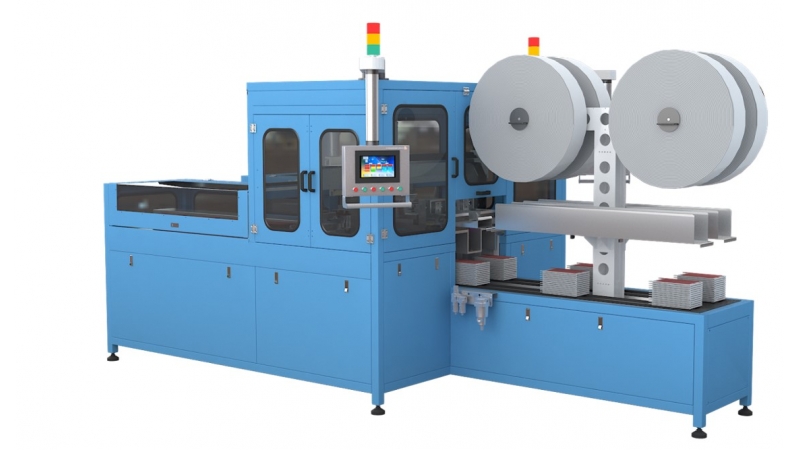

product model:

production rate:

energy and consumption: AC380V; 50HZ; 27KW(max)

standard power:

E(production ):AC220V; 50HZ; 1KW(max)

applicable grid range:

type(separator paper ):

Number(matched pieces):

.jpg)

E(production ):AC220V; 50HZ; 2KW(max)

applicable grid range:

type(separator paper ):Wrapping the positive plate into AGM separate paper by U sharp.

Number(matched pieces):

.jpg)

product model:

production rate:400-500 pcs of batteries per shift.

energy and consumption:

standard power:

.jpg)

product model:

production rate:

energy and consumption: AC220V; 50HZ; 2KW(max)

standard power:

.jpg)

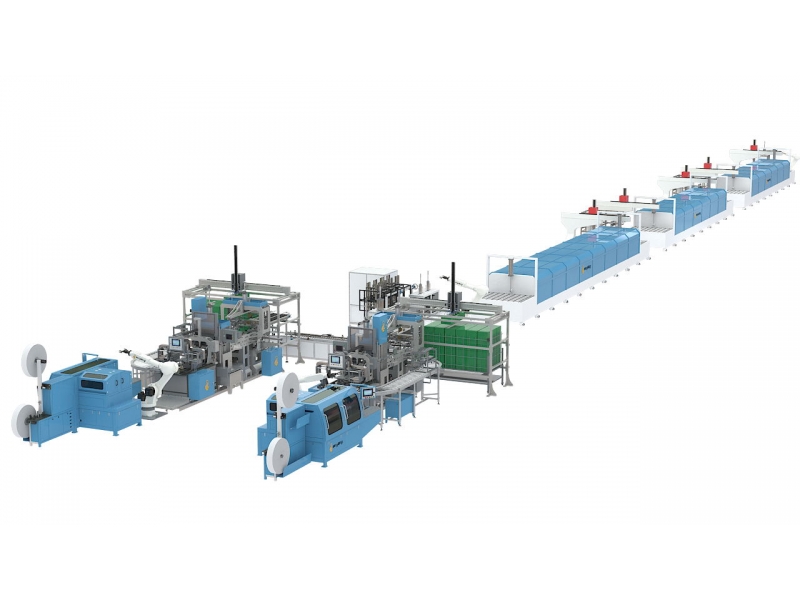

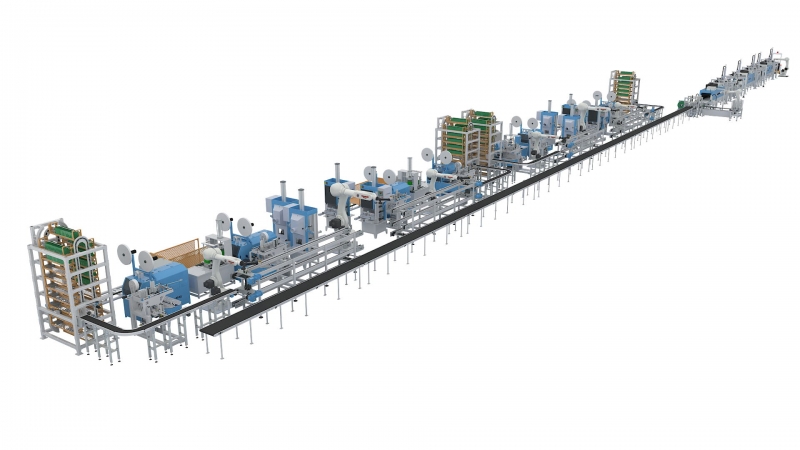

capacity:5000-6000 per line per shift.

E(production ):

overall dimension:

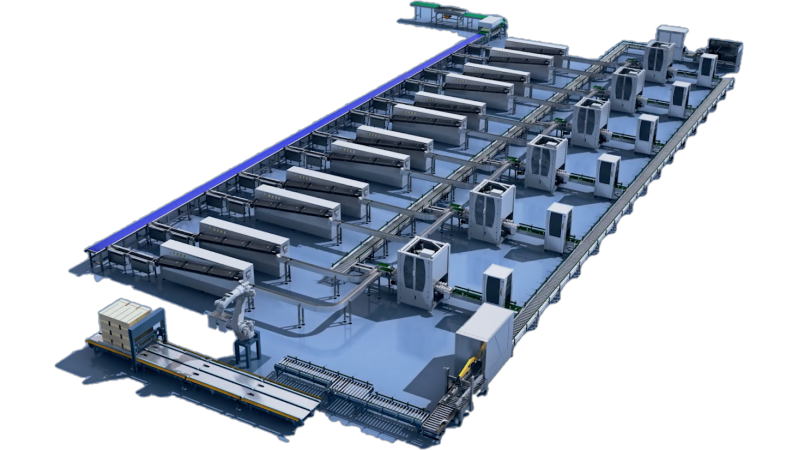

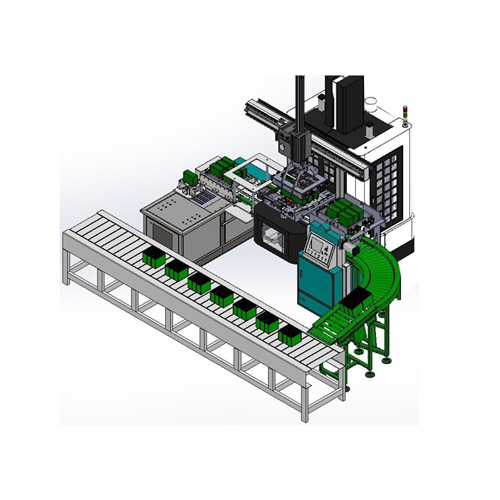

workflow:12 AFFWM / 12 fixturing machines / 6 cutting-brushing slotting machine. 8 articular Robot and subsidiary assembly lines.

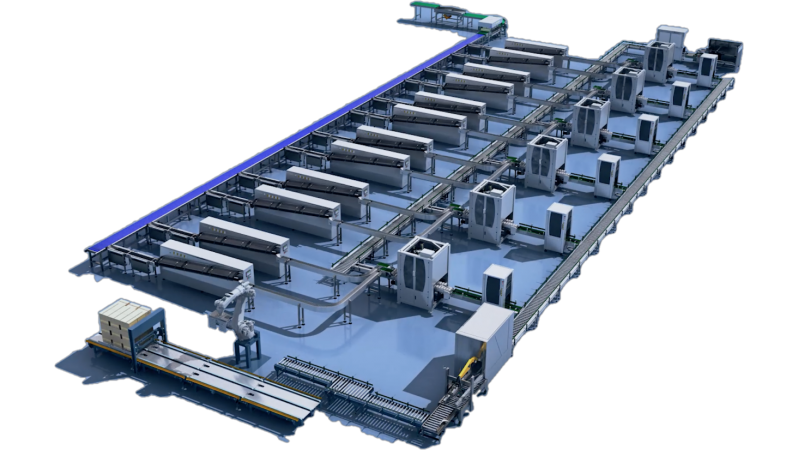

capacity:800-1000 batteries/ line, signle shift.

E(production ):

overall dimension:

workflow:All type medium and large scale lead acid batteries capacity from 65ah to 150ah.

work efficiency:单班产能400-500只中大密电池

installed power:According to customer requirements

overall dimension:L:5000mm W:1600mm H:2650mm

size:3.8T

work efficiency:30~50秒/周期

installed power:5~10L/min 1m3/min

overall dimension:L:1000mm W:600mm H:1200mm

size:According to customer requirements

E(production ):切刷时电机转速 1400r/min, 切刷动作用气缸运行速度可通过调节

grid size:小密极板

installed power:刷轴电机1.1KW或1.5KW(选配) 切轴电机0.75KW或1.1KW(选配)

overall dimension:L:1440mm W:750mm H:800mm

work efficiency:According to customer requirements

area covered:以实际情况为标准

Scope of application:中小密电池

total power:以实际情况为标准

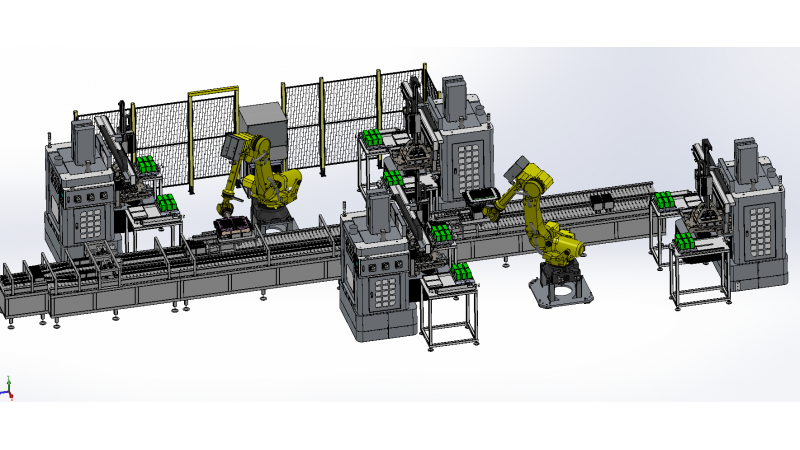

capacity:以机器人铸焊机1对2 20AH电池为例,单机单班产能可达到5000-6000只电池

E(production ):以机器人铸焊机1对2 20AH电池为例,单机单班产能可达到5000-6000只电池

overall dimension:采用机器人配合铸焊机实现整线集成布局,占用生产空间小,更加具备环保性及安全性

workflow:整体切刷——铸焊工序

work efficiency:According to customer requirements

area covered:According to customer requirements

Scope of application:According to customer requirements

total power:According to customer requirements

capacity:每条线每班产能5000-6000只

E(production ):According to customer requirements

overall dimension:According to customer requirements

workflow:12台熔焊机 / 12台包片入夹一体机 / 6台切刷入槽一体机。8台机械手及辅助流水线

capacity:整线单班产能800-1000只

E(production ):According to customer requirements

overall dimension:According to customer requirements

workflow:全线具备生产信息的采集、分析能力,稳定性极高。再配合海悦最新空气能烘箱技术,可使能耗降低70%以上。省人、节能、降耗效果明显

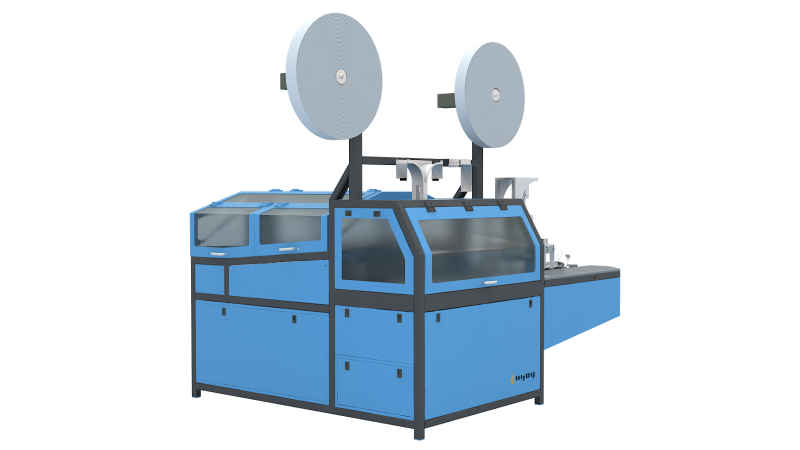

E(production ):以负板为例, 每增加1片负板, 包片速度增加1-1.3秒。(20AH单班产能600-700, 12AH单班产能480-550只电池)

applicable grid range:小密极板

type(separator paper ):AGM

Number(matched pieces):按照客户需求

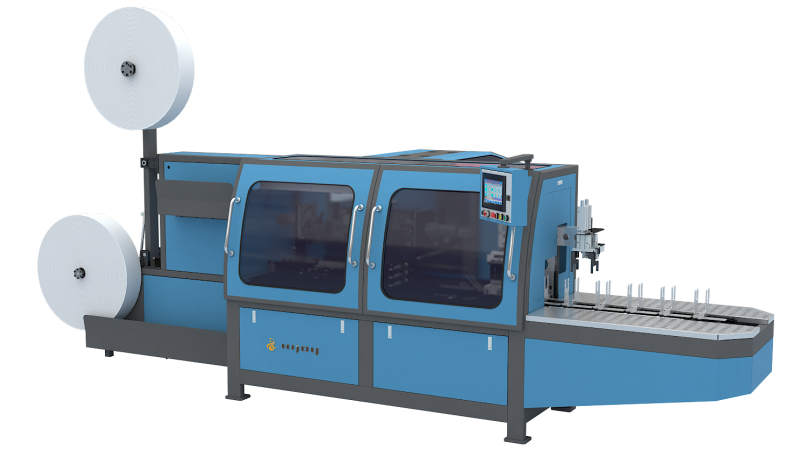

E(production ):以负板为例, 每增加1片负板, 包片速度增加1.3-1.6秒。(20AH单班产能600-650, 12AH单班产能450-550只电池)

applicable grid range:小密极板

type(separator paper ):AGM

Number(matched pieces):A. 单开双通道不配组包片 B. 单开双通道配组包片 C. 三通道配组包片

E(production ): 负板片数基础上增加2秒 (如4正5负为5+2=7秒)

applicable grid range:中密极板

type(separator paper ):AGM隔板

Number(matched pieces):隔板纸宽度在120mm-180mm范围内可调 极板高度在100mm到240mm范围内可调 适合AGM隔板纸U型正板包法, 极板片数为3正4负到9正10负范围内可调

product model:中大密自动烧焊机

production rate:多工位生产,每班产能在240只电池左右

energy and consumption:≤2kW

standard power:AC220V@50HZ

E(production ):包正板或负板(负板片数X1.5+1.5)秒/单体 , 正负板都包(负板片数X2.5+1.5)秒/单体

applicable grid range:中大密 (包括2V系列电池)、适合隔板纸单包正板、 单包负板或者正负板都包三种方式的U型包法

type(separator paper ):PE隔板

Number(matched pieces):24正25负

work efficiency:70~90秒/周期

installed power:三相五线AC380V/50Hz;60kW(最大)

overall dimension:L:1400mm W:1853mm H:2688mm

size:以实际应用为准